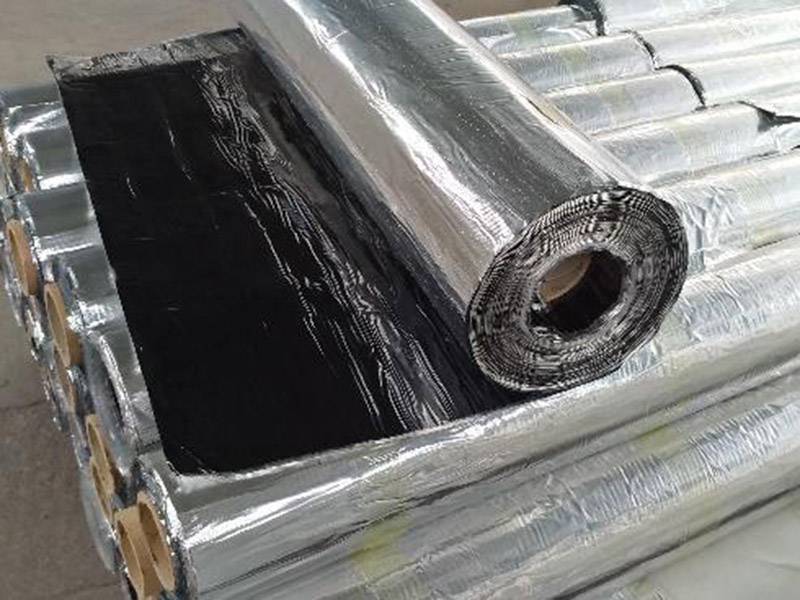

APP Modified Bitumen Membranes

APP modified bitumen membrane

APP-modified bitumen membrane is made by saturating the base in bitumen, or thermoplastics (such as APP, APAO, APO), then covering double faces with a thermoplastic elastomer (SBS) and lastly finishing the upward face with fine sands, mineral slates (or grains) or polythene membrane, etc. while the downward face with fine sands or polythene membrane.

Characteristic:

Good impermeability; Possess good tensile strength, elongation rate, and size stability which could be well suited the substrate distortion and crack; SBS-modified bitumen membrane is specially applied in the cold area with low temperature, while APP-modified bitumen membrane is applied in the hot area with high temperature; Good performance in anti-puncture, anti-broker, anti-resistance, anti-erosion, anti-mildew, anti-weathering; Construction is convenient, the melt method can operate in four seasons, joints are reliable.

Specification:

| Item | Type | PY: Polyester G: Glassfibre PYG: Glassfibre enhance polyester feltPE: PE FilmS: Sand M: Mineral | ||||||

| Grade | Ⅰ | Ⅱ | ||||||

| Reinforcement | PY | G | PYG | |||||

| Surface | PE | San | Mineral | |||||

| Thickness | 2mm | 3mm | 4mm | 5mm | ||||

| With | 1000mm | |||||||

Applicable scope:

Suitable for civil building roofing, underground, bridge, parking, pool, and tunnel in the line of waterproofing and dampproof, especially for building under high temperatures. According to the roofing engineering stipulation, APP-modified bitumen membrane could be used in the Grade Ⅰ civil building and industrial building which has special waterproofing requirements.

Storage and transportation instructions

l When storage and transportation, Different types and sizes of products shall be stacked separately, and should not be mixed. Storage temperature should not be above 50℃, the height is not more than two layers, and n the course of transportation, the membrane must stand.

l The stacking height is not more than two layers. To prevent the tilt or pressure, when necessary cover the felt fabric.

l In normal conditions of storage and transportation, the storage period is a year from the date of production

Technical data:

APP

[Confirming to GB 18242-2008]

| No. | Item | Ⅰ | Ⅱ | ||||||||||||

| PY | G | PY | G | PYG | |||||||||||

| 1 | Soluble content/(g/m²)≥ | 3cm | 2100 | * | |||||||||||

| 4cm | 2900 | * | |||||||||||||

| 5cm | 3500 | ||||||||||||||

| Test | * | No flame | * | No flame | * | ||||||||||

| 2 | Heat resistance | ℃ | 110 | 130 | |||||||||||

| ≤mm | 2 | ||||||||||||||

| Test | No flow, no dripping | ||||||||||||||

| 3 | Low temperature flexibility/℃ | -7 | -15 | ||||||||||||

| No crack | |||||||||||||||

| 4 | Impermeability 30 minutes | 0.3MPa | 0.2MPa | 0.3MPa | |||||||||||

| 5 | Tension | Maximum/(N/50mm) ≥ | 500 | 350 | 800 | 500 | 900 | ||||||||

| Secondly-Maximum | * | * | * | * | 800 | ||||||||||

| Test | No crack, no apart | ||||||||||||||

| 6 | Elongation | Maximum/%≥ | 30 | * | 40 | * | * | ||||||||

| Secondly-Maximum≥ | * | * | 15 | ||||||||||||

Standard: GB18243-2008

product description:

This product is based on polyester felt, glass fiber felt, glass fiber reinforced polyester felt, random polypropylene (APP), or polyolefin polymer (APAO, APO) as a modifier, both sides are covered with fine sand Waterproof membrane made of isolation materials such as mineral particles (sheets) and PE film.

Variety specification:

Class: Type I; Type II

Width: 1000mm; 2000mm:

Thickness: 3.0mm; 4.0mm; 5.0mm

Product features: suitable for building waterproofing in high-temperature areas.

Scope of application: It is suitable for waterproofing and moisture-proofing roofs of industrial and civil buildings, as well as waterproofing buildings such as bridges and parking lots.

Construction Notes

Construction is not allowed on rainy days, snowy days, and windy days above level five.

The construction process adopts fusion lap joints, and the occurrence of over-fire and under-fire should be avoided. It is advisable to melt the oil out of the lap joints, and the width of the oil out is 5-10mm.

For shale coils, the overlapping parts of the short sides should be sanded to improve the bonding strength.

The safety protection facilities for the construction site and personnel are complete, and the fire-fighting equipment is effective and placed in accordance with regulations.